item:- coal mine, fire

goto source

goto sourceGentleman's Magazine 1747 p.326 "..."

"Extract of a Letter from Whitehaven, May 16."

"A False account having been put into the news papers about several of our coal pits near this town being on fire, and burning in the most dreadful"

item:- coal mine, fire; firedamp

goto source

goto sourceGentleman's Magazine 1747 p.327

"manner, it may be proper to publish the truth. - Some of the coal-pits near this town are probably the deepest of any in the world, and therefore subject to fire-damps; so that, if a great deal of foul or inflammable air, by neglect or mischance, is collected together under ground, and is set on fire, it goes off with a very great explosion, and does great damage to what it meets with in its way to vent itself at the pit's mouth. - Where the foul air is very strong, as it is often at the sinking of new pits, it is brought up in pipes along the sides of the pit into the open air, and a candle, or lighted paper, being put to the end of the pipe, it will break out into a flame, one or two feet in breadth, and several feet in height, more or less, according to the quantity of foul air that is vented, and will burn day and night for months and years. The flame of it may easily be seen at the Isle of Man, which is ten leagues off, and affords a better light to shipping than the light-house; and yet may be generally extinguished by laying a wet sail over it. - Sir James Lowther, to whom this colliery belongs, had thoughts of making a fire-engine with it, had there been occasion for one where it arises: it therefore may be esteemed one of the greatest natural curiosities which is any where to be met with † "

"This colliery is the most curious and extensive in its kind; it hath been wrought above 100 years, and above a million sterling hath been expended in carrying it on; some parts of the works are carried under the sea, and are 200 yards deeper than the surface of the sea, which is probably nearer to the earth's center than any miners have penetrated in any other place."

"On the 6th of April last, by means of some defect in the partitions, or pipes to carry off the foul air, there happened a very great explosion, which beat down a good deal of the partitions, and some of the stops under ground, and a part of the coal took fire by the damp, which kept burning as it issued out of the crevices, and several other blasts or explosions happened for a day or two, but not so violent. For several days afterwards there was no explosion, nor any thing to be observed, but a little smoak and a sulphureous smell at one or two of the pits, till the 20th of April, when there were two more explosions, and two more on the 22d, some of which were so violent, the blast carried all that was loose before it, and threw up to the top of the pit, tho' 160 yards deep, a strong wooden stage, covered with earth, clay, stones, &c. and let down to stop the air going down the pit, and to resist a smaller explosion; since that day such methods have been taken, that there has been no explosion, and nothing to be observed at the top of the pit but a little smoak, and a sulphureous smell, so that there can be at worst but a small fire, if any, which there is little doubt will soon be extinguished. It has pleased God, this whole affair, which was set forth in so terrible a manner (see p.246 E) has not cost the life or limb of any one person."

" † This fire-damp, or thick mine air, may be contained in bladders, and has been sent in that manner to London, &c. It is a true kind of air, tho' inflammable, being a subtile and permanently elastic fluid, which is easily rarified by heat, and condensed by cold, as may be proved by holding a bladder not quite fill'd with it to the fire. By its elastic spring it also expands itself as soon as the pressure of the incumbent atmosphere is taken off; thus the bladders, which were not quite fill'd with it at the bottom of a deep pit, are violently distended when brought to the top in a lighter air. The same may be demonstrated by putting some of it in a bladder close tied, under the receiver of an air-pump, and exhausting some of the air contained in the receiver."

"In regard to its inflammability, contrary to gun-powder, it will not take fire at a red-hot iron, or at the sparks made by the collision of a flint and steel, but is readily kindled by a lighted candle, or any other flame; and if pressed out of a bladder thro' a pipe stopple, and so set on fire, it continues burning at the end of the stopple as long as it is pressed out. But if the flame of a candle be suddenly introduced into a bladder fill'd with it, so as to fire it all at once, it goes off with a considerable explosion like gun-powder; and thus resembles what the miners call a blast; which sometimes proves destructive to them, when a large quantity of this inflammable air is collected together in the mines, and there, by some accident, set on fire."

item:- coal mine, fire; fire, coal mine

goto source

goto sourceGentleman's Magazine 1747 p.246 "Whitehaven, in Cumberland. One of the coalpits belonging to Sir James Lowther near this place, being set on fire by the carelessness of a boy, it burnt with great fury, and communicating itself to 6 pits, was become a very shocking scene, prodigious quantites of smoak, earth, pieces of timber, and materials used in the work, being continually thrown out, with an inconceivable noise, and shaking of the earth, so that the inhabitants were in fear for their houses."

"The Coal Mines at Whitehaven are well worth the traveller's inspection, as they are, perhaps, the most extraordinary of any in the known world. The principal entrance into these mines is by an opening at the bottom of an hill, through a long passage hewn in the rock, which by a steep descent, leads down to the lowest vein of coal. The greatest part of this descent is through galleries, which continually intersect other galleries; all the coals being cut away, except large pillars, which, in deep parts of the mine are three yards high, and about twelve yards square at the base, such great strength being there required to support the ponderous roof. The mines are sunk to the depth of 130 fathoms, and are extended under the sea to places, where is, above them, depth of water for ships of large burthen. These are the deepest coal mines that have ever yet been wrought. Those who have the direction of these deep and extensive works are obliged, with great art and care, to keep them continually ventilated with perpetual currents of fresh air; and where these precautions are not taken, large quantities of damps are frequently collected. These often remain for a long time without doing any mischief; but when, by any accident, they are set on fire, they then produce dreadful explosions, very destructive to the miners; and, bursting out of the pits with great impetuosity, like the fiery eruptions from burning mountains, force along with them ponderous bodies to a great height in the air. The late Mr. Spedding, who was the great engineer of these works, having ob-"

"served"

MG02q013.txt

"[ob]served, that the fulminating damp could be kindled only by flame, and that it was not liable to be set on fire by red hot iron, nor by the sparks produced by the collision of flint and steel, invented a very curious machine, in which, while a steel wheel is turned round with a very rapid motion, and flints applied thereto, great plenty of fire sparks are emitted, which afford the miners such a light, as enables them to carry on their works in a close place, where the flame of a candle or a lamp, would occasion dreadful explosions. There are five engines belonging to this colliery, which, when all at work, discharge from it about 1228 gallons every minute, at thirteen strokes, and, after the same rate, 1,768,820 gallons every twenty-four hours. (See Burn's Cumberland, Vol.II. p.44, &c.)"

item:- shipping; coal; fire engine (pumping engine); pumping engine; strata, coal; corf

goto source

goto sourcePage 180:- "..."

"... Whitehaven ... The collieries lie at the foot of an hill 80 fathoms deep, by an easy descent bricked and vaulted. The town and collieries produced a revenue of 16,000 a year to the late sir James Lowther, who had here a magazine of oats, which he always sold to the colliers at 5s. per bushel Cumberland or three Winchester measure"

"... about 260 sail ships of near 30,000 tuns burthen. Thirty of them are employed in foreign trade and the rest in the coal trade, and export yearly above 20,000 tuns. He devised his estates here to sir William Lowther of Holker, bart. who dying the next year was succeeded in the said estates, reckoned 14,000£. a year, by the present sir James Lowther, ... The coal mines here are perhaps the most extraordinary in the world; sir John Lowther, father of the late sir James, first worked them for exportation, and he and his son in the course of half a century are supposed to have expended in one of them about half a million sterling. The mines are sunk to a depth of 130 fathom, and extended under the sea to places where there is over them a depth of water for ships of large burthen. Here are three strata of coal at a considerable distance, one above another, but not always regular, being interspersed by breaks of hard rock called dykes. Four fire-engines belong to this colliery, which, when all at work, discharge from it about 1228 gallons every minute at 13 strokes, and after the rate of 1,768,620 gallons in 24 hours. ..."

"Sir John Clerk, in a letter to Mr. Roger Gale 1739, gives this account of Whitehaven and its collieries:"

""The greatest curiosity at Whitehaven is sir James Lowther himself; whenever his death happens it will be much felt by the people of this place, for when his money comes to be divided the coal will be set in farm and consequently brought to the verge of ruin. Amongst the extraordinary works of this place, I could not but admire those on the sea-coast to the westward. The sink goes down"

goto source

goto sourcePage 181:- "perpendicularly 80 fathom below the sea (I suppose low-water mark), and many underneath it. Sir James's riches in part swim over his head, for ships pass daily above the very ground where his colliers work. The coals are drawn up by an engine, worked by two horses, which go a full trot every eight hours, and three changes are employed in a day and a night. The quantity drawn up is about twenty corfs in an hour, each corf consisting of an oblong square 32 inches long, 18 broad, and 22 deep, which cost 7d.½ Thus I found the quantity of coal brought up in a year (Sunday excepted), amounted to about 4,200£. but out of this the colliers and other expences being paid, he cannot clear above 500 or 600£. a year, out of this his largest coalwork. He draws the water from his coal-seams by a fire-engine with four pumps and four lifts: one of the pumps goes down 80 fathoms, which brings up the water to a cistern at 60 fathoms deep; from thence another pump raises it to cistern of 40 fathoms deep from the surface on the top of the sink; a 3d brings it up to 20, and a 4th to the level of the sea at high water. The cylinder which gives life to this motion is of brass 42 inches diameter, fixed in a boiler of about 11 feet diameter. The coal, when brought up to the level of the sea, is put in ships, and conveyed to the cavity of a hill, whence it is drawn up by a second engine. There it is put on great carts with low wheels, which gently roll down to the harbour on oak boards. The method of shipping it is no less curious. The strata are five or six inches, the largest six feet thick, and sometimes seven or eight. The next is five feet. One is three, another two feet. Though the coal at Newcastle be much exhausted near the sea, the strata continue all the way to Corbirdge and Hexham, but at Whitehaven the strata are almost spent to the length of Workington, at least no great fields of coal remain. It is, however, certain, that some seams stretch towards Newcastle, and are the same though broken and interrupted, sometimes lying flat, sometimes on edge, sometimes three or four feet thick, sometimes scarce an inch; in which alteration I have sufficiently observed here and in Scotland. ...""

item:- coal; firedamp; Bannock Band coal seam; Main Band coal seam; steam engine; spedding mill

goto source

goto sourcepage 151:- "In Hutchinson's History of Cumberland, it is stated that "The Coal Mines at Whitehaven are perhaps the most extraordinary of any in the known world. Sir John Lowther, father of the late Sir James, was the first that wrought them for foreign consumption. It has been computed that the said two gentlemen, in the compass of a century, expended in one of them only upwards of half a million sterling.""

"The principal entrance to the Colliery at that time seems to have been along the dip of one of the important seams which comes out to the surface, as it is stated that - "The principal entrance to these mines, for men and horses, was through a long passage hewn in the rock, which by a steep descent leads down to the lowest vein of coal. The greatest part of this descent is through spacious galleries, which continually intersect other galleries; all the coal being cut away except large pillars, which in deep parts of the mine are three yards high and above twelve yards square at the base; such great strength being required to support the ponderous roof.""

"The historian, however, apparently misunderstood the information he had obtained, because the entrance he describes was evidently to some of the shallowest workings, as he goes on further"

goto source

goto sourcepage 152:- "to state that - "The mines are sunk to a depth of an hundred and thirty fathoms, and are extended under the sea to places where there is above them sufficient depth of water for ships of large burden," Then he goes on to say, - "These are the deepest coal mines that have hitherto been wrought, and perhaps the mines have not, in any other part of the globe, penetrated to so great a depth below the surface of the sea.""

"The presence of fire damp, or fulminating damp, as it was then called, was recognised to be a source of peril to miners, and it is stated that the coal was several times set on fire by it, and that it continued burning for months, until large streams of water were conducted into the mines and permitted to fill those parts where the coal was on fire."

"Mr. Carlyle Spedding, the chief engineer of Lord Lonsdale's Collieries, having observed that the fire damp was not liable to be ignited by red hot iron, nor by sparks from flint and steel, but by flame only, invented a machine in which a steel wheel was made to revolve rapidly while flints were pressed against it, producing a stream of fiery sparks which gave sufficient light to enable the men to work in comparative safety, but the machine did not afford absolute protection."

"At the commencement of the work at Whitehaven a level was driven from the bottom of the valley, near Pow Beck, to the south of the town, and it was continued on until it intersected the Bannock Band; afterwards another level was driven from Pow Beck, near the farm-house called "Thicket," still more to the south. By continuing this level westward the Main Band was intersected, and these two levels drained and made available a large area of the seams names, but only a limited quantity could be won without sinking shafts. At first the coal was brought up the pits by jack rowls and primitive windlasses, and later by horse windlasses called ginns. The water also had to be drawn up by these ginns, but as the pits became deeper, and the workings more extensive, better and more powerful machinery had to be provided. Sir James Lowther is said to have purchased in London, and brought to Whitehaven by sea, the first steam engine that was erected in the North of England. The engine was erected at the Ginns, a village built for the quarry workmen, and called by the name of the ginns in use there for raising coal and water."

"As the number of pits and the extent of the workings increased, the quantity of water in the mines also increased, and the number and power of the engines had to be increased in proportion. Some were erected at a place called Saltom, near the sea, about a mile south-west of the town. "One of these engines had two boilers of fifteen feet diameter each, and a seventy inch cylinder. The pumps attached to it were eleven and a half inches in diameter, with a six and a half feet stroke, and"

goto source

goto sourcepage 154:- ""were capable of raising four hundred and five gallons of water per minute from a pit seventy-five fathoms deep." The produce of the Whitehaven Colliery at that time is not stated, but it is acknowledged that it occupied the first place with regard to output, and the extent of its workings."

placename:- Whitehaven Colliery

click to enlarge

click to enlargePST342.jpg

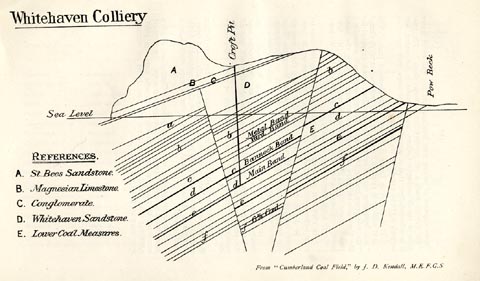

On p.153 of Mines and Mining in the English Lake District, by John Postlethwaite.

printed, upper left "Whitehaven Colliery"

printed, lower right "From "Cumberland Coal Field," by J. D. Kendal, M.E.F.G.S"

item:- JandMN : 162.44

Image © see bottom of page